What is High Velocity Oxygen Fuel(HVOF)

- High Velocity Oxygen Fuel (HVOF) coating is a thermal spray coating process, which is used to improve or restore a component's surface (properties or geometry).

- This surface engineering technique better enables life extension of equipment by increasing erosion and wear resistance, and corrosion protection.

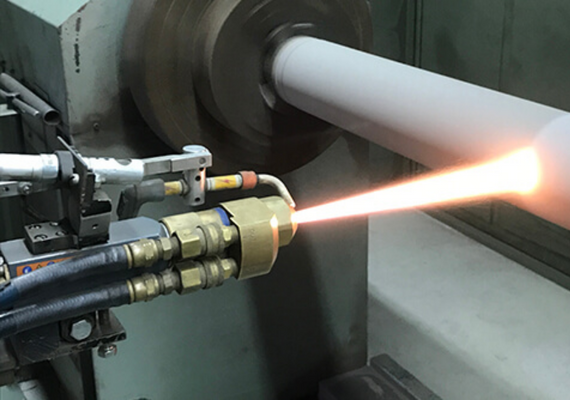

- HVOF spraying was developed in the 1980s and is a subset of thermal spraying. HVOF spraying works by mixing fluid fuel and oxygen, which is fed into a combustion chamber and ignited.

- The resultant gas has an extremely high temperature and pressure, which is ejected through a nozzle at supersonic speeds. To the high velocity gas stream, powder is injected,

which partially melts.

- The stream of hot gas and powder is directed towards the surface to be coated. The resulting dense coating has low porosity and high bond strength,

providing many benefits such as corrosion resistance